8. Jan. 2026

The clean laboratories of the CEITEC Nano research infrastructure at CEITEC Brno University of Technology house a four-meter-tall TITAN transmission electron microscope for researching materials at the atomic level. This scientific device underwent two significant upgrades this year, entailing the addition of two state-of-the-art technologies: an electromagnetic lens aberration corrector for scanning transmission electron microscopy and an electron energy loss spectrometer equipped with cameras featuring today's most sensitive sensors. Thanks to these upgrades, TITAN has become a state-of-the-art device that can only be found in a few of the world's most advanced laboratories in this configuration.

The TITAN Themis microscope was manufactured in 2015 by FEI (now Thermo Fisher Scientific) and has been in use at CEITEC BUT since 2016. At the time of its acquisition, it was one of the most powerful commercially available electron microscopes; however, it lacked a corrector for optical defects in the lenses that form the narrow electron beam scanning the sample. This meant limited resolution and a lower ability to analyze the chemical composition and physical properties of materials at the atomic level.

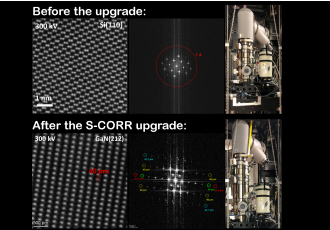

"The latest generation S-CORR aberration corrector allows the electron beam to be focused to a size up to twice smaller than an atom, while also providing a higher electron current. This has led to a significant increase in the resolution and analytical capabilities of the microscope," explains Jan Michalička, guarantor of the TITAN microscope. "Thanks to the new corrector, our microscope achieves the world's highest standard in resolution, specifically less than 50 picometers at an acceleration voltage of 300 keV." For better understanding, he adds a comparison: "Imagine the ratio of the size of a golf ball to that of planet Earth. That is exactly the ratio of an atom measuring 100 pm to a golf ball." Thanks to this resolution, scientists are not only able to image individual atoms, but also to determine their chemical nature through further analysis. This is of fundamental importance, for example, for the development of new catalysts for a more environmentally friendly chemical industry.

The new corrector also allows the microscope to achieve high resolution even with low-energy electrons. This is crucial for studying highly sensitive materials such as graphene and other two-dimensional structures, which would be damaged by a stronger electron beam. "Electrons interact strongly with the sample and can damage it at the atomic level, for example, by changing its structure and chemical composition. With the new corrector, we can achieve atomic resolution even at the lowest acceleration voltage of 60 keV, allowing us to study even very sensitive materials in a virtually unchanged state," says Jan Michalička.

The additional installation of a corrector at the CEITEC laboratory is unique worldwide

Correctors of optical defects in electromagnetic lenses are an exceptional technology that has completely changed the world of electron microscopy. For a long time, they were considered technically impossible, and the absence of correctors essentially prevented research into the structure and properties of materials at the atomic level. It was not until the 1990s that a group of four scientists – Harald Rose, Max Haider, Knut Urban, and Ondřej Křivánek – succeeded in implementing this technology, for which they received the prestigious Kavli Prize in 2020. “Correctors basically consist of a pair of complex lenses, each containing a series of magnetic multipoles. In the case of the correctors invented by the first three scientists mentioned above, defects are removed by two hexapole lenses. Our new corrector is based on the same concept,” adds Jan Michalička.

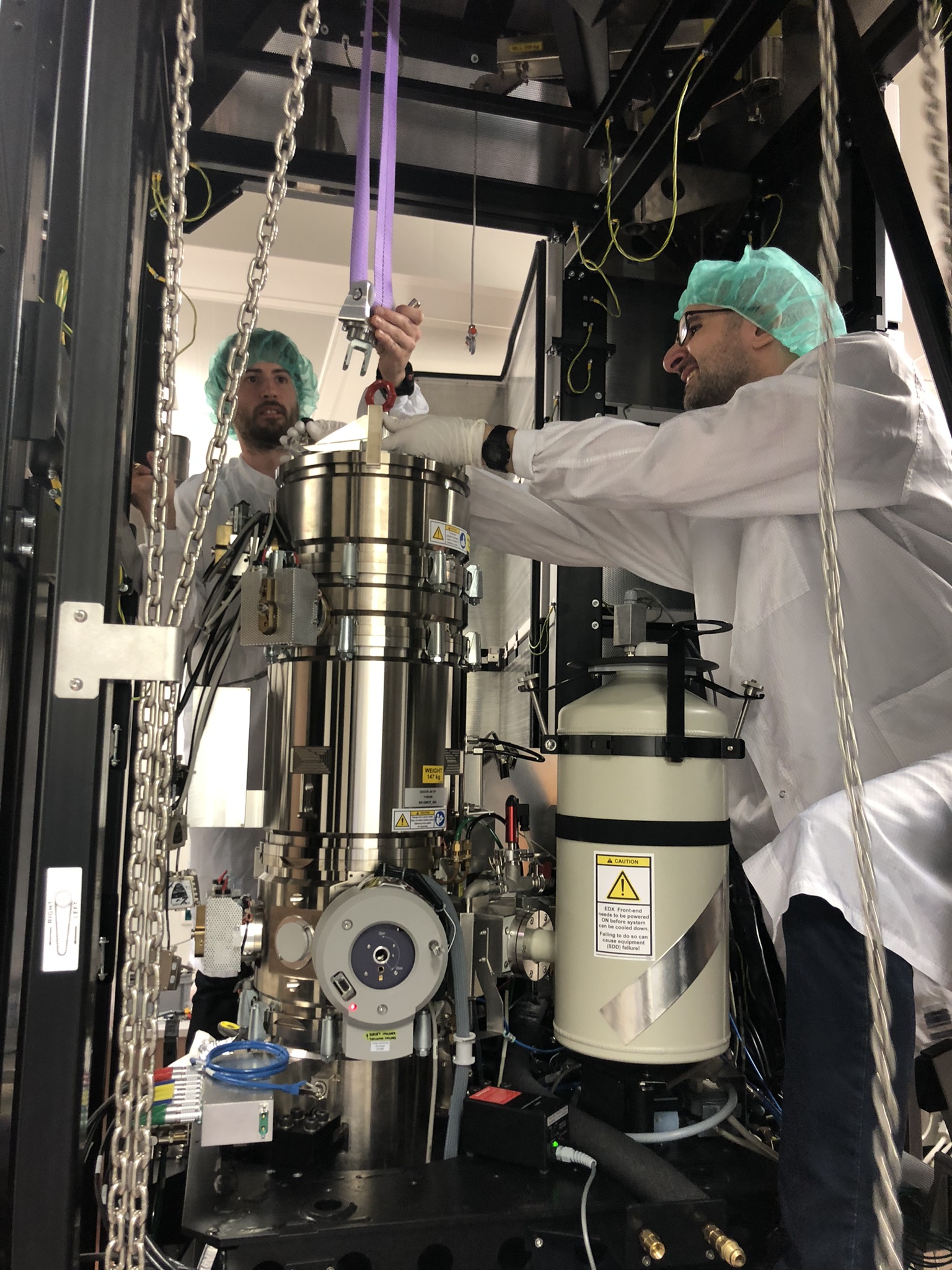

The additional installation of a corrector is unique in itself nowadays. Similarly complex technologies are usually installed during the manufacture of microscopes in the factory, in this case in the Netherlands. However, in Brno, the microscope was successfully upgraded with a corrector under the limited conditions of the laboratory. The installation of the corrector took about four months and required the dismantling of a large part of the microscope. "With this installation, we basically went back to the time when the four scientists mentioned above placed their prototype corrector on an older microscope, thus improving its performance," says Jan Michalička with a smile, adding that the most difficult part was the precise adjustment of the corrector and the entire optics of the microscope in order to achieve top parameters. "Even though most things are now controlled by computers, there are only a few people in the world who can install and tune a corrector to the highest level of accuracy. We are therefore extremely pleased to have had such experts at our disposal here."

New spectrometer will enable scientists to see more

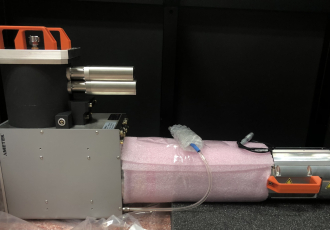

The second and equally important upgrade to the TITAN microscope is the installation of the latest generation GIF Continuum HR electron energy loss spectrometer by Gatan. This is an approximately two-meter-long device installed horizontally under the microscope, whose main component is a magnetic prism that separates the electron beam according to their energy losses. The spectra of these losses provide enormous information about the sample, principally at the atomic level, as they are characteristic of the given state of the atoms, such as the valence arrangement of their electron shell. In combination with the new corrector, the spectra can be used to analyze the chemical bonds, arrangement in the crystal lattice, or the entire range of physical properties of atomic nanostructures down to the level of individual atoms.

An essential part of the spectrometer are the state-of-the-art K3 and Stela cameras, which can directly detect and count individual electrons. At the same time, these cameras are extremely fast and their sensors capture data without noise. "These features of our cameras are key to measuring sensitive or dynamically changing samples and allow us to obtain information that was previously invisible to electron microscopes," says Jan Michalička.

Last but not least, the spectrometer will open up completely new possibilities for measuring the magnetic properties of atomic structures. The new spectrometer will also be used for such experiments within the project TERAFIT, which financed this upgrade, and which focuses on research into materials for ultra-high capacity, speed, and energy efficiency in information technology. "The device is fully prepared for advanced experiments and the use of modern software tools, including artificial intelligence," adds Vojtěch Uhlíř, head of the Nanomagnetism and Spintronics research group at CEITEC BUT and one of the TERAFIT project investigators, highlighting the advantages of the spectrometer.

Together with the corrector, the spectrometer represents a breakthrough in the analysis of material properties, and according to Jan Michalička, CEITEC now has one of the most powerful microscopes available. “In modern materials science, for example, in the development of magnetic memories, quantum materials, or 2D structures, it is necessary to see not only atoms, but also their behaviour in real time, including magnetic states. And it is this spectrometer that pushes the boundaries of what we can see and analyze.” Michal Urbánek, head of the CEITEC Nano laboratories and coordinator of the large research infrastructure CzechNanoLab, agrees with him, adding that the device can now contribute to scientific knowledge on a global scale. “Thanks to its integration into the large CzechNanoLab research infrastructure, this state-of-the-art microscope is accessible not only to scientists from CEITEC, but also to other institutions in the Czech Republic and abroad.”

Do you want to know more? Read the expert version of this article.

Share

Share