24. Sept. 2025

[September 22, 2025] A three-year European project called MOSAIC was launched in Gdańsk, Poland, with the aim of conducting extensive research in the field of electronic components and systems. CEITEC BUT also participated in the initial meeting of the consortium of partners from academia and industry on behalf of the Czech Republic. Within the project, CEITEC BUT will focus on the development of a special sensor for electromobility.

The international MOSAIC project, with a total budget of €56 million, is financially supported by the European Union and the Ministry of Education, Youth and Sports as part of the CHIPS JU initiative. Led by the German technology company Infineon Technologies, it involves 46 partners from 15 countries in Europe, the Middle East, and Asia. The scientific community includes, for example, the prestigious Fraunhofer Institute in Germany, Bar-Ilan University in Israel, the Taiwanese ITRI Institute, which is known for its excellent research in the field of industrial technologies, and the Czech CEITEC BUT, which focuses primarily on research in the field of materials science.

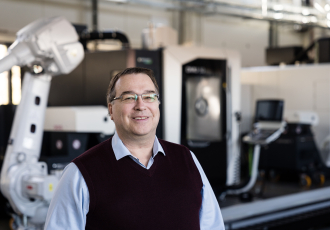

“The purpose of this project is to develop a series of new sensors for the automotive industry, robotics, and infrastructure. These sensors will enable, for example, fast data processing and intuitive decision-making with the support of artificial intelligence,” explains Pavel Václavek, principal investigator of a sub-project developing a fiber optic magnetic field sensor for electric drive diagnostics. He adds that MOSAIC also emphasizes standardized communication protocols and system compatibility, which is key for industrial use.

“During this two-day introductory consortium meeting, we will focus primarily on planning the individual phases and coordinating the initial research activities so that the partners can start working together as soon as possible.”

Magnetic fields and artificial intelligence in the leading role

The optical fiber sensor, which is to be developed at CEITEC BUT over the next three years, will work on the principle of detecting changes in the magnetic field and will be able to record even the slightest errors in engine operation. “The magnetic field affects the optical properties of the fiber, and we will be able to measure these changes. Based on the values obtained, it will then be possible to use other data and artificial intelligence models to monitor the condition of the engine and assess whether it is working properly or showing signs of damage,” explains Václavek. The sensor system will thus not only enable the detection of ongoing technical faults and an appropriate response, but also the prediction of minor damage that could lead to more serious malfunctions in the longer term.

Although researchers at CEITEC BUT have been studying the magnetic properties of materials for a long time, this project is completely unique at the institute. “In the past, we solved similar tasks using existing sensors that measure the electric current in the motor winding. This time, however, we are focusing on magnetic field deviations, which could lead to a major technological breakthrough with great potential not only in the field of electric motor diagnostics, but also in other industrial equipment,” adds Václavek.

At least five experts from the Cybernetics and Robotics research group led by Pavel Václavek at CEITEC BUT will be continuously working on the development of the new fiber optic sensor. For demanding mathematical modelling and simulations, they will use Nvidia DGX A100 and DGX H100 computing systems, which have been part of the RICAIP Testbed Brno scientific infrastructure since last year.

“These supercomputers provide powerful tools for massively parallel computing. In addition, both computing nodes are connected by an InfiniBand network with a transfer speed of up to 200 Gb/s, which ensures extremely fast and efficient communication between systems,” explains Václavek. The testing of the physical sensor model will also take place at RICAIP Testbed Brno, which has not only IT infrastructure but also a wide range of industrial testing equipment, including complete equipment for testing drives and converters.

“The result of our research will be functional technology verified in a laboratory environment close to reality, which can be developed through further research and subsequently applied in practice in the future,” he concludes.

Author: Kristina Blűmelová

Share

Share