27. Oct. 2025

It all started with a well-equipped laboratory and the desire of Přemysl Šťastný from the Advanced Ceramic Materials research group at CEITEC BUT to create suspensions for 3D printing of less common ceramic materials. Within a few years, this individual work became a successful project involving four scientists, which now has great potential to succeed on the market under the name 4Slurries and offer custom production of these suspensions.

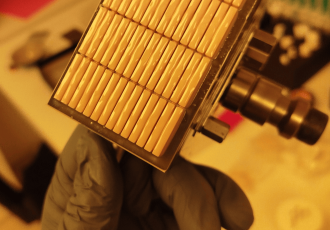

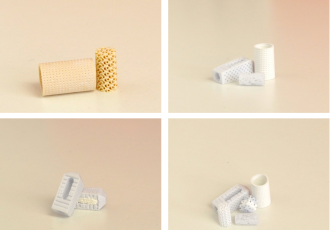

One of the most common ways to produce a ceramic 3D print is to use binder jetting technology, in which objects are created layer by layer by selectively applying a liquid binder to a bed of powder, typically aluminum oxide. The binder then holds the powder particles together and creates a solid structure. But to understand what 4Slurries team is working on, one has to imagine a completely different technology – one that uses the principle of photopolymerization, i.e., curing material using light with a wavelength of, for example, 465 nm (blue light). One of the printing methods using photosensitive materials is called DLP (digital light processing) and involves the use of digital light projection to cure an entire layer of the printed object at once. In the processing of ceramic materials, a photosensitive suspension with a honey-like consistency is used for printing, containing both the ceramic powder itself (e.g., aluminum oxide or zirconium oxide) and a binder in the form of various (not only) monomers that act as an adhesive.

Our own path to the know-how of the big players

Although there are several manufacturers of DLP 3D printers on the global market who also develop their own suspensions, virtually all of them target their products primarily at common industrial applications, for which materials such as the aforementioned aluminum oxide or zirconium oxide are sufficient. However, science and industry know of many other powder materials for less common, one-off, or small-batch applications that no one has yet mixed into suspensions. “Large companies do not engage in research into the ideal ratios and material composition of such suspensions because it doesn’t make sense economically for them, and as I gradually learned at conferences, no one else is able to mix such suspensions in the quality required for a 100% result. So I decided to focus part of my research at CEITEC on this,” recalls Přemysl Šťastný, referring to the beginnings of the 4Slurries project, and adds that the biggest obstacle to the development of suspensions is that these fluids are not fully transparent due to scattered particles and scatter light in all directions. Ultimately, this means that during printing, due to light scattering, the suspension is also cured in places where it is not desired, and as a result, the finished prints are not identical to the model. “So I started looking into photopolymerization and light scattering on particles and how to deal with this effect, which took about a year before the first positive results came in. That is, the suspensions cured only where we wanted them to during exposure, and the resulting component had the intended geometry.”

However, according to Přemysl Šťastný, finding the optimal composition of the suspensions was not easy at all. “I had to figure out what each component in the system would affect. The mixture requires various substances that must react with each other or, conversely, must not react with each other. Balancing them to get the right result actually took hundreds of hours in the lab.” At the same time, it was important to make the suspensions in such a way that the binding component could be removed by a thermal process after the printing of the object, without causing any cracks in the body. Only then is it possible to achieve a flawless material after the final sintering.

Přemysl initially worked on the research alone, with support from group leader Martin Trunec and Klára Částková. He was later joined by Eliška Šiška Virágová, who also studies advanced ceramic materials at CEITEC, as well as colleagues Jan Pišťák, Pavlína Šárfy, and, later, Erik Šćasnovič. Together, they finally managed to find a mechanism for mixing suspensions from different powder materials with the desired result. Knowing that they had a very promising know-how that had a chance of success outside the laboratory, they entered the project in the internal CEITEC Technology Transfer Competition. “I must say that we were very responsible when approaching this. We came up with the entire concept, including the logo and name, which is composed of the term for these suspensions (slurries) and a number that referred to us, the number of people involved. We also prepared a presentation in which we explained the goals of our project and its possible practical applications to the jury,” adds Eliška Šiška Virágová, noting that the team won the competition and thus obtained funding for further development of the project and its presentation and promotion at conferences and on social networks such as LinkedIn. “We all saw this win as a driving force that began to propel us forward, both in our own scientific work and, of course, in our efforts to raise awareness among people in the field and beyond,” continues Přemysl.

In less than a year since its success in the CEITEC Technology Transfer challenge, the 4Slurries project has reached a stage where it has all the technological know-how at its disposal and is able to offer interested parties a finished product tailored directly to their requirements. “With a little exaggeration, I can say that when someone brings us basically any ceramic powder, we return a suspension with specific parameters needed for both the printing itself and the subsequent processing of the print, because more than 1/3 of the volume is lost during the removal of the binder and sintering. And, of course, we have all the material sheets stored away, so it's no problem to return to any mixture or use its composition as a basis for innovations,” he continues, adding that requests to mix suspensions have already started coming in not only from colleagues at CEITEC who are working on other projects, but also from colleagues at the Czech Academy of Sciences and several companies in the industry. Cooperation has also begun on a cross-border academic basis, specifically with the FGK institute in Germany. The 4Slurries project is therefore well on its way to becoming a commercial entity in the future. “For now, we are trying to build the brand and awareness, while financing development from internal resources of our research group. However, these collaborations are also a promising start, and if it turns out that this is a concept that has a chance on the market, we are ready to take the next step and launch a spin-off, which means we would try to succeed on our own,” conclude the two young scientists on behalf of 4Slurries.

Author: Kristina Blűmelová

Share

Share